Horizontal vs. Vertical Autoclaves: What are the Differences?

Introduction

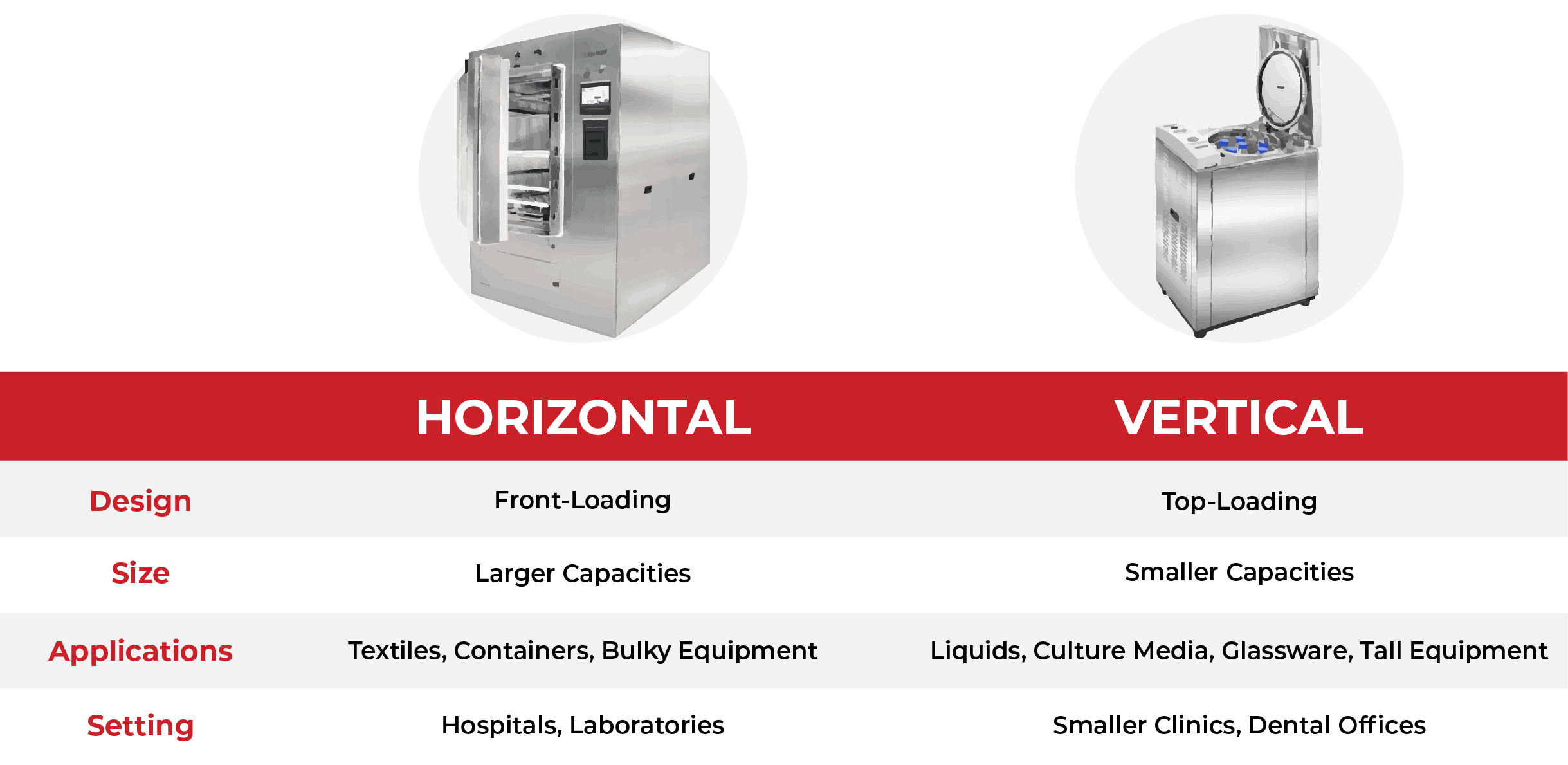

Autoclaves are used in various healthcare and lab environments to thoroughly sterilize medical equipment. Among the various options available, horizontal and vertical autoclaves offer unique advantages based on chamber orientation, load capacity and more.

Both types are highly effective for sterilizing liquids, culture media, instruments, glassware, plastics, and contaminated materials. Ultimately, your facility’s needs will determine which type of autoclave you should purchase. In this article, we’ll go over the key differences between horizontal and vertical autoclaves.

Horizontal vs. Vertical Autoclaves

What is a Horizontal Autoclave?

Horizontal autoclaves are large, high-capacity sterilization units designed for laboratory and industrial applications. Also known as front-loading autoclaves, horizontal autoclaves are longer yet shorter in height, making them easier to load and unload. Additionally, horizontal autoclaves are used in hospitals and research labs for bulk sterilization.

What is a Vertical Autoclave?

Vertical autoclaves are top-loading sterilization units designed for facilities with limited space. With a slimmer yet taller design, these autoclaves are compact and ideal for smaller clinics and laboratories. The top-loading design allows for the sterilization of liquids, glassware, and taller items that need to remain upright.

Differences between Horizontal and Vertical Autoclaves

Closing

The key to selecting the right autoclave comes down to evaluating the type of loads, frequency of use and available space for your laboratory or medical facility. To view our full catalog of autoclaves, click here.